Why work with us?

For projects large and small, we have been a trusted community resource for more than 10 years.

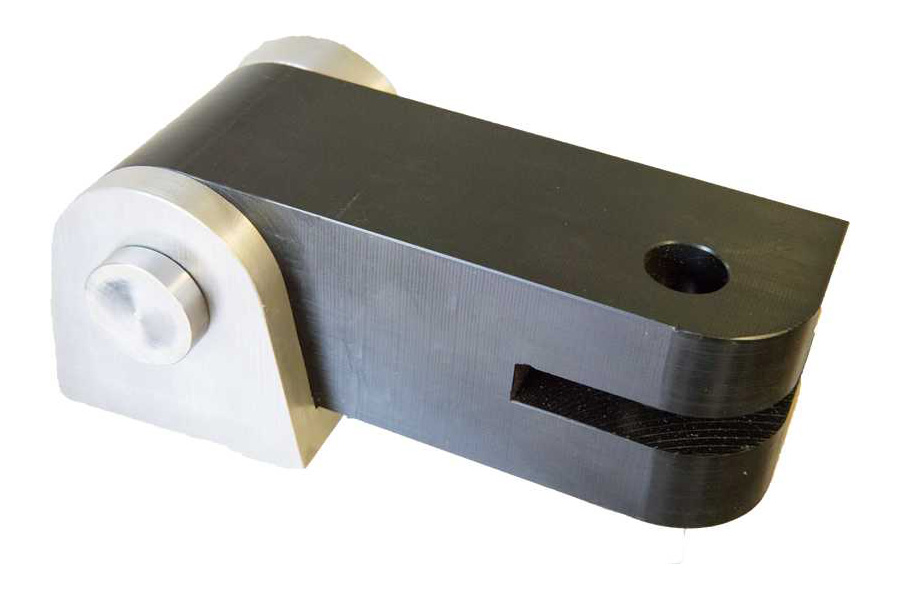

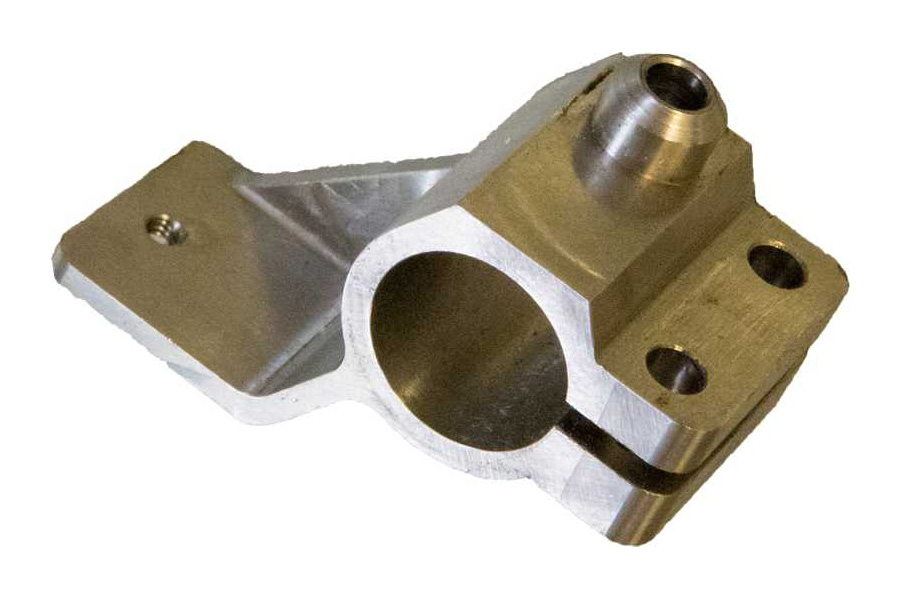

We manufacture from print to part.

We do our own CAD work and machine programming.

We inventory your repeat part needs to reduce cost of manufacturing.

Our standard lead time is two to three weeks, though we can accommodate rush orders.

We provide on-time delivery.

We have access to welding fabrication, laser and waterjet cutting services, heat-treating as well as large turning and milling.

We work with a variety of materials and machinery

Materials

Machinery

- Steel

- Stainless Steel

- Alloy Steel

- Tool Steel

- Plastics

- Aluminum

- Torlon

- Peek

- Acetal

- PET

- UHMW

- Celizole

- HDPE

- Mazak QT30

- CNC Turning Center

- Capacity 12” x 30” 30-horsepower 1-position turret

- 10” chuck, programmable tailstock

- Mazak VCN510C 2004 model

- CNC 3 AXIS milling center

- Capacity 20” x 20” x 40”

- 25-horsepower spindle

- 30-station tool changer

- 12000 RPM

- High-pressure coolant

- Mazak VCN510CII 2007 model

- CNC 3-Axis milling center

- Monarch manual 15” x 60” manual lathe

- Lagun milling machine 10 x 54 3hp spindle

- Broaching press up to 1/2″

Contact us today to discuss the right solution for your business.

"*" indicates required fields